George Lesnansky

Slowly but surely, Brookfield school Superintendent Toby Gibson has worked toward changing the educational culture of the school, making more hands-on learning opportunities available to students as opposed to book learning, and injecting more science, engineering, technology and math into the curriculum.

With the award of a $60,000 grant from the Arconic Foundation, the district will expand its

“maker space,” add tools to its entrepreneurship class and maybe even give members of the public a chance to make some really cool stuff.

The grant will be used to buy equipment such as T-shirt and button presses, a sublimation machine and a vinyl cutter; train teachers in their use; and open a Spirit Shoppe, a student-run business that will make and sell Brookfield Warrior T-shirts, hoodies, hats, stickers and other items.

“The sky’s the limit on what they can create,” Gibson said.

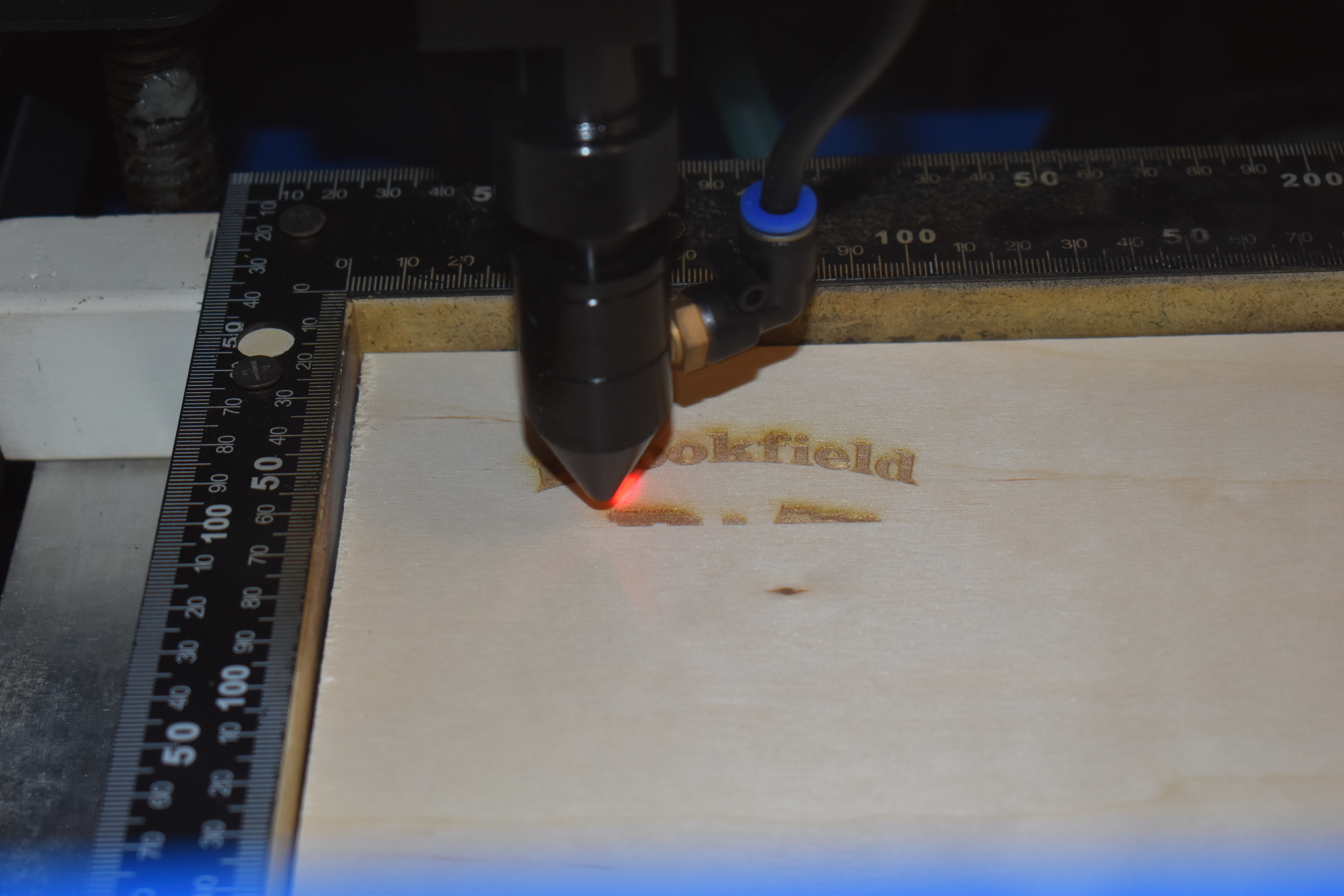

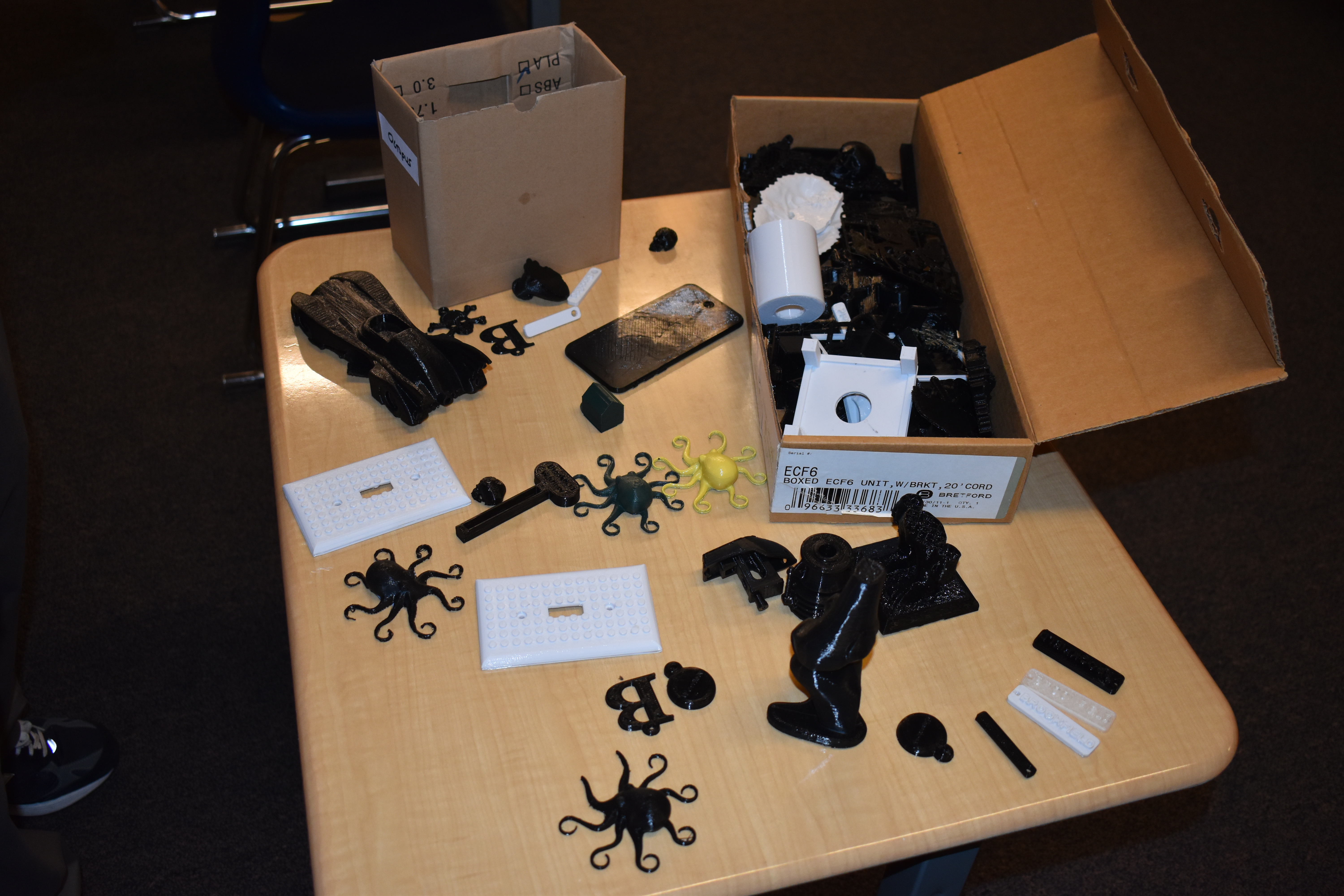

The equipment will be added to 3-D printers, a laser engraver, a CNC router and other pieces on hand that have been used by students to create key chains, models and award plaques for inductees into the Brookfield Distinguished Alumni and Athletic Halls of Fame.

By January, Gibson hopes to have the high school entrepreneurship class creating the Spirit Shoppe and selling goods at lunch time; later, at school events.

“It’s an opportunity to create and produce and manage a business,” he said. “It’s an opportunity to problem solve.”

The equipment will come under the oversight of teacher George Lesnansky.

“We’re hoping to create a space where students can make stuff,” he said.

That’s essentially what a maker space is: a place to make stuff using technology and simple materials such as plastic, wood and glass.

By making stuff that’s Brookfield-related, the students will be “promoting our brand,” Lesnansky said.

Showing the equipment already on hand and the kinds of things students have produced, such as an anatomically accurate replica of a knee, etchings on wood of their own signatures and even a Batmobile, Lesnansky noted that the maker space has not been built through the spending of tax dollars.

“All these things came from grant writing and the generosity of different corporations,” he said.

“All these things came from grant writing and the generosity of different corporations,” he said.

Materials come from donations, discount purchases and scavenging, such as wood pallets that were going to be thrown away.

Students have to learn how to use software, take measurements, and fit dimensions to the scale of the material available.

“Everything’s a math problem,” Lesnansky said.

While a 3-D printer works slowly depending on the complexity of what it’s making – the Batmobile took nine hours to print – and time is the school’s “biggest enemy” because of limited class times and the number of students looking to make items, the new equipment will allow students to make something much more quickly, Lesnansky said.

“We’re trying to make it better and bigger, more and more stuff,” he said.

Once the staff learns to use the new equipment and students start making stuff, Gibson said he would like to organize a program where members of the public get a chance to use it.

“It’s a fun place to hang out,” Lesnansky said.

A laser engraver in action.

Items Brookfield students made with a 3D printer.